Asheville Residents - Learn Lean Six Sigma’s History Here

Contact Us

When looking at LSS’s history, you will need to be familiarized with several methodologies. Or, at least, to do some research. We can help you learn all about LSS at Lean Six Sigma Curriculum for Asheville High School Students of North Carolina. Our team is experts in this method, and we have deep knowledge about all aspects of it. You will benefit from what we know and all the details you can learn about Sigma, starting right here!

First, you must understand that this methodology was created to help companies prioritize their customers and increase their earnings. It combines the principles from Six Sigma and Lean as well, so learning about both methodologies individually will help exponentially.

If done right, the methodology can help reduce costs and eliminate waste. It is important to maintain quality and performance throughout the process, and while doing all this, it can increase customer satisfaction and results, depending on how it’s implemented.

LSS combines the two methods previously mentioned. Kaizen and other methodologies have also influenced how practitioners and companies see their industries and what they need to accomplish the desired results.

It is important to focus on the basics and remember that the methodology improves quality and processes. Although the core principles of Lean and 6 Sigma are important, there is more to it than what’s already in place when combining them into Lean Six Sigma.

LSS is believed to be Japanese due to the Kaizen method. This Japanese method was a huge help to Japan’s manufacturing sector as it encouraged members and all companies to be more attentive and to provide better products. This led to increased production and manufacturing, and American companies were even left behind based on the results Japanese businesses were getting.

LSS’s past history will prove that it is not just a solution for Japanese businesses that have had better results in recent years than American companies of the late 80s. It was actually when all things began.

Inception & Utility: Learn More About Lean 6 Sigma

Six Sigma and Lean, concepts well-known for decades, are still in use and they are essential before you move on to the end LSS and how the main methodology works.

Toyota invented Lean in the 1940s as a way to reduce non-value-adding activities. This is where you should start when looking at the entire LSS history.

Lean believes employees should be actively involved in organizational change to foster excellence. Continuous learning and improvement are key pillars to ensuring everyone is happy and achieves the desired outcomes.

It was founded on the foundations of Japanese Taiichi Ohno and the Toyota Production Systems (TPS), Henry Ford’s innovations, and Business Process Redesign.

This is how Lean should be viewed when you work in it:

- Lean starts with understanding your customer’s added value and how you can help them.

- You can map the value streams and the waste that you want to eliminate.

- Do your best to reduce or eliminate waste.

- Next, Lean refers to the process of setting up the system so customers can request it and then delivering it to them when they are ready.

- Employees will be able to identify and work together to solve problems.

- This allows all parties to be able to think through the whole process and concentrate on customer needs efficiently.

These are the fundamentals of Lean. Now, Six Sigma is data-driven; Motorola invented the method, and General Electric successfully used it in the 1980s.

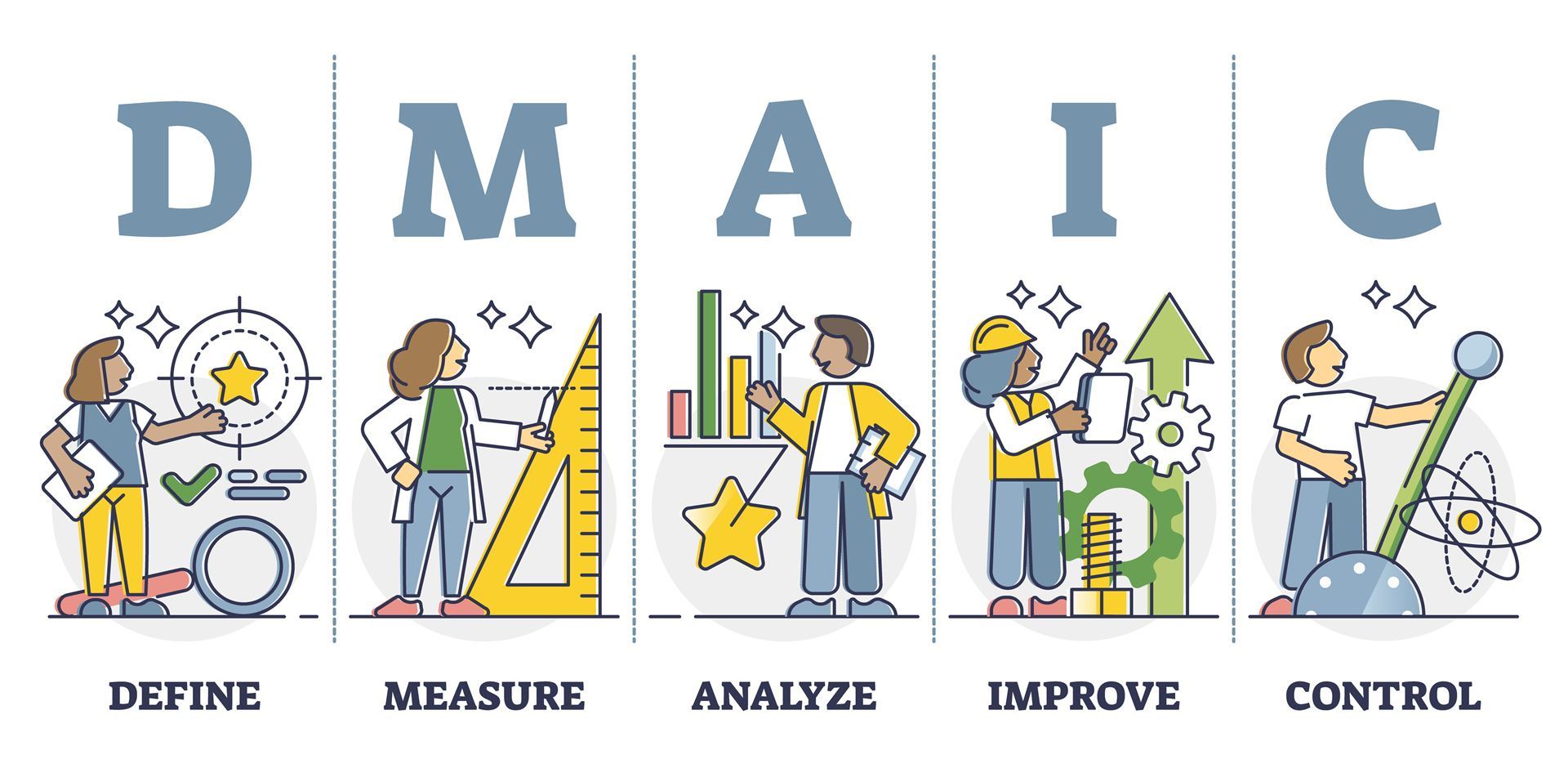

Six Sigma is built on the DMAIC option. This tool is great for manufacturing and other industries to automate processes, identify problems, and find solutions, and it also reduces the time it takes to address issues.

Lean Six Sigma & How It Works Today

Companies liked Lean and 6 Sigma as stand-alone methods, so they combined them to create a system that is more focused on continuous improvement when facing competitors in the late 80s.

American companies had to adapt in the 1980s to Japanese companies when Kaizen and other methods were making products better and making American companies fall behind.

The efficiency provided by LSS allowed us to obtain valuable insight into the industry and the USA to grow without compromising customer service. The point of LSS was to ensure that better results and processes were possible.

This method is also used in other areas than product development. Education and healthcare are looking for ways to reduce the amount of time and resources required to improve their systems and are taking advantage of it today.

Lean Six Sigma Curriculum Pros of Asheville is committed to offering training to anyone who wishes to learn the methodology and help them become certified.

We are always available for advice and suggestions. Contact us today to find out more about LSS and become a member.